Grooving Tools

Boring, Grooving, Face Grooving, Chamfering, Profiling, Backboring, Threading

Cassette System 960 Compatible with Grooving System 845

Find the required HORN part numbers based on individual machine types.

- Select from the drop down menu:

- Machine Manufacturer

- Machine Type

- Results will be:

- Matching item number for base plate

- Matching item numbers for tool holder

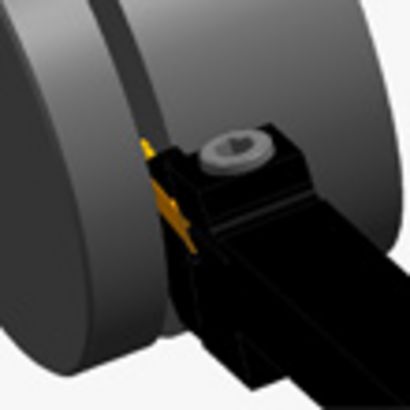

Supermini® Type 105/109/110

Tool system for machining smaller bores:

More than 1,200 standard inserts can be clamped in a toolholder.

- Boring out from bore diameter 0.2 mm

- Grooving from bore diameter 2 mm

- Axial grooving from diameter 5 mm

- Chamfering, profiling, backboring and threading

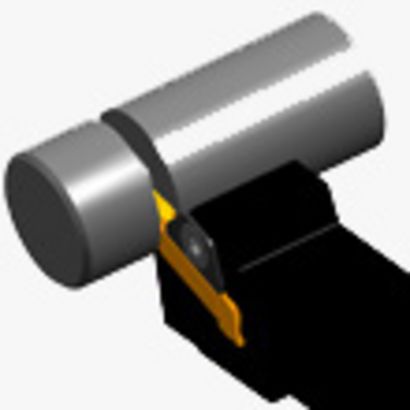

Mini Type 106 / 107 / 108 / 10P / 111 / 11P / 114 / 116 / 18P

Tool system bolted on face side with low vibration carbide toolholders

- Boring out from bore diameter 7.8 mm

- Grooving from bore diameter 8 mm

Large selection of inserts for different applications, e.g. chamfer, full radius, thread, backboring

Grooving System S274

Tooling system for lathes, used for grooving, turning, parting off and threading

External machining:

- Cutting width 0.5 mm to 2.0 mm

- Grooving depth tmax = 6.0 mm

- Metric thread pitches P = 0,25 - 1,5 mm

- Backturning internal apmax = 6.0 mm

- Parting off tmax = 6.0 mm

- Exceptionally fine-ground sharp cutting edges

- Screwed inserts

Geometries available for steel and brass machining

Grooving System S209

Tool system for grooving and for internal machining

- Bore diameters from 16 mm

- Cutting width from 2 mm to 3 mm

- grooving depth tmax = 3.5 mm

- Toolholders with shank diameter D = 16 mm

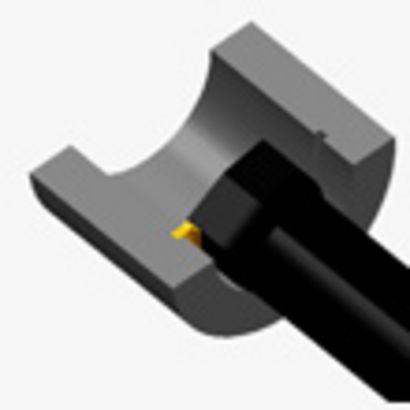

Internal Grooving with System 216

Tool system for grooving and for internal machining

- from bore diameter 20 mm

- Cutting width from 2 mm - 6 mm

- Grooving depth tmax = 7.5 mm

- with internal coolant supply

Grooving System 217

Tool system for grooving, internal and external machining

Internal machining:

- Bore diameters from 18 mm

- Cutting width from 0.5 to 5.3 mm

- Grooving depth up to 4.7 mm

- Toolholder 245 and the cutting insert for corner relief

External machining:

- Groove width 0.5 mm to 5.3 mm

- Grooving depth up to 4 mm

Grooving System 264

Tool system for Swiss-type lathes for grooving, longitudinal turning, parting off and threading

- External machining: Grooving width 1.5 to 3 mm

- Grooving depth up to 16 mm

- Special geometries for steel and brass machining

Grooving System S119/S123/S223

Tool system for grooving, turning, profiling and parting off

Internal machining:

- Bore diameters from 16 mm

- Grooving width 1.2 mm to 3.0 mm

- Grooving depth tmax = 6.3 mm

External machining:

- Cutting width 1.2 to 3.0 mm

- Grooving depth up to 10 mm

Parting off:

- Grooving width 2.0 mm to 3.0 mm

- Parting off diameter up to 50 mm

Grooving System 224

Tool system for grooving internally and externally, face grooving and for parting off

Internal machining:

- Bore diameters from 28 mm

- Grooving width from 2.0 mm to 6.0 mm

- Grooving depth tmax = 8 mm

External machining:

- Groove width 2.0 mm to 6.0 mm

- Penetration depth tmax = 18 mm

Grooving:

- Toolholder with cassette system

- Outer diameter from 47 mm to 1000 mm

- Grooving depth tmax = 14 mm

Available geometries:

.3, .5, .A, .D, .NC, .K, NC, .E, .F, .H, .L

Indexable Insert S224 with Internal Coolant

With .3V geometry for stainless steels

- Cutting width 3 mm

- Grooving depth tmax = 18 mm

Grooving System 229/S229

Tool system for grooving, internal and external machining, face grooving and parting off

Internal machining:

- Bore diameters from 38 mm

- Grooving width 3.0 mm to 10 mm

- Grooving depth tmax = 15 mm (depending on diameter)

External machining:

- Grooving width 2.5 mm to 10.0 mm

- Grooving depth tmax = 26 mm

Grooving:

- Holder with cassette system

- Outer diameter of 60 mm to 1000 mm

- Grooving depth tmax = 25 mm

Parting off:

- Cutting width 3 mm to 5 mm

- Penetration depth tmax = 25 mm

- Parting off diameter: max. 150 mm

Available geometries:

.3, .5, .A, .E, .F, .H, .L, .HR, .10, .20

Grooving System 231

Tool system for grooving, internal and external machining and for face grooving

Internal machining:

- Bore diameters from 70 mm

- Grooving width 4.0 mm to 10 mm

- Grooving depth tmax = 9.5 mm

External machining:

- Grooving width 2.5 mm to 10.0 mm

- Grooving depth tmax = 11 mm

Face grooving:

- From outside diameter Dmin = 40 mm

- Cutting width from 3 to 10 mm

- Grooving depth tmax = 8 mm

Available geometries: .3, .10, .20

Grooving System 312/S312

Tool system for grooving, internal and external machining, face grooving and parting

Internal machining:

- Bore diameters from 46 mm

- Cutting width up to 5.3 mm

- Grooving depth tmax = 5 mm

(depending on diameter)

External machining:

- Grooving width 0.5 mm to 5.3 mm

- Grooving depth tmax = 8 mm

Face Grooving:

- Groove width 2 to 3 mm

- Grooving depth tmax = 3 mm

- From outside diameter Dmin = 20 mm

Available geometries: .00, .V, .F, .5, .D, .C

Triple-edged Grooving Insert S34T

Tool system for external grooving:

- Usable as neutral, left-hand and right-hand insert

- No additional clamping elements necessary

- Screw head does not generate interference contour

- Cutting widths: 2 mm / 2.5 mm / 3 mm

- Cutting depths up to 6.5 mm

Available in geometries .3, .5, .D

Grooving System 315

Tool system for grooving for internal and external machining

Internal machining:

- Bore diameters from 43 mm

- Grooving width 0.5 mm to 5.29 mm

External machining:

- Grooving width 0.5 mm to 8.0 mm

- Grooving depth tmax = 5.0 mm

Threading of:

- Trapezoidal threads

- Metric coarse threads

- Metric fine threads

Face grooving:

- Cutting width: 2.0 mm to 3.0 mm

- Grooving depth tmax = 3.0 mm

- From outside diameter Dmin = 20 mm

Form stitches:

- Cutting widths up to 15 mm

Grooving System S316

Tool system for grooving and external machining

External machining:

- Grooving width 2.0 mm to 3.0 mm

- Grooving depth tmax = 8.0 mm

Available geometries: .52, .EN2 and .FY

Face Grooving System 25A

Face grooving system with round shanks and cassettes for the common cassette interface K220, suitable for all corresponding HORN toolholders.

Internal coolant to the cutting point for efficient cooling. The .10. geometric shape ensures reliable chip flow.

- One- and two-edged inserts

- Outer diameter of 15 mm

- Cutting depths up to 20 mm

- Cutting widths from 2 to 4 mm

Grooving Categories

Tools for Swiss-type Lathes

Individual solutions for Swiss-type lathes.

Matched connections for the following machines:

- Star

- Tornos

- Citizen

Modular Tooling System

Mounting system with cassette for the following connections:

- HORN polygon shank according to ISO 26623

- HORN tool holder according to TS ISO 26622

- HORN HSK according to DIN 69893

- HORN HSKT according to DIN 12164

Cassettes solutions for the following systems:

- S100

- S224

- S229

- 312

- 315

Cassettes for face grooving:

- S224

- S229

Face Grooving

Face grooving with the following systems:

- 105/110

- 114

- 312

- 315

- S224

- S229

Starting from outer groove diameter of 5 mm

Profiling S117

External machining preferably on multi-spindle

- Profiling grooving inserts with a width of 10 to 45 mm

- Tread depth up to 13 mm

- Inserts with customized profile according to customer specification

- Toolholder for AWN or PWP system available

Parting Off

- Large selection of parting off solutions

starting with cutting width 0.5 mm

- Toolholder systems with DIN shanks and blades for the following insert systems:

- S274

- S264

- 312 / S312

- S316

- 123/223

- 224

- 229 / S229

- S100

- Solid carbide blades for grooving and parting off on lathes

Broaching Systems SB105/S110/SH117

Manufacture of longitudinal grooves according to DIN 138 and DIN 6885 on CNC lathes and machining centers

- Grooving width from 2 mm

- Tolerance classes:

- C11

- JS9

- P9

For direct mounting in the machine as well as mounting in a live broaching attachment from the companies BENZ, EMS, Schwarzer, Ar2P and WTO