Special Applications

HORN develops custom tool solutions specific to your application.

Application Example 1: Multi-grooving "Petrol Piston"

Grooving Radial

The grooves are machined with PCD-tipped inserts type 312 which are clamped in a multi-grooving toolholder - toolholder type 340.

Process:

- Pregrooving

- Finishing with a second set of inserts

Material: GD-AlSi12

Cutting Data Pre Grooving:

Vc = 350 m/min

Vf = 0,03 mm

Cutting Data Finishing:

Vc = 350 m/min

Vf = 0,07 mm

Application Example 2: Face Grooving on Gear Wheel

Using Horn-Capto toolholder type 360 and special indexable insert Type 312.

The size of the burrs along the teeth defines the tool life and creates a high technical demand on the tool itself.

Material: 20MnCr5

Cutting Data:

Vc = 200 m/min

Vf = 0,06 mm

Application Example 3: Hardturning on Gear Wheel

GROOVING OF HARDENED PARTS

Special CBN-tipped insert type S117 is used to finish the width of the groove. The stock removal is approximately 0.15 - 0.2 mm (.006˝ - .008˝). The insert is ground to the final width of the groove.

Both flanks are machined at the same time (Rz=2.3 μm). To obtain high surface finish, the insert has a wiper flat on both of the side cutting edges. Stable machining conditions are imperative. No coolant.

Material: 20MnCr5

Case Hardened 58-62 HRC

Cutting Data:

Vc = 140 m/min

Vf = 0,08 mm

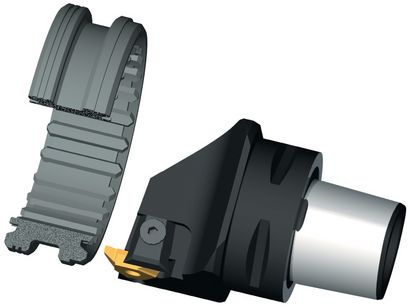

Application Example 4: Face Grooving - Multi Tool

Based on the insert system S224. The tool is used to do a front and back face grooving operation.

The toolholder is equipped with exchangeable and adjustable cartridges.

Material: 20MnCr5

Cutting Data:

Vc = 180 m/min

Vf = 0,16 mm

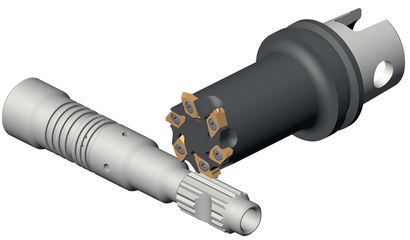

Application Example 5: Groove Milling (by Circular Interpolation)

Grooving Head type 389 with HSK

Example: Wheel cylinder

Tool data:

Cutting edge Ø Ds = 39 mm

Number of teeth Z = 6

Material: C45

Cutting Data:

Vc = 180 m/min

Vf 3 = 3913 mm

tg = 1,92 sec

Application Example 6: Groove Milling on Swivel Bearings

GROOVE MILLING (by Circular Interpolation)

A set of milling cutters - type M275 with different cutting diameters are used. They are mounted on a HSK arbor with through coolant. All operations - Grooving and Facing - are done in one step.

For multi-spindle use on transfer lines, the length adjustment is done by distance rings.

The example shows a detail of a swivel bearing with tool. Dry cutting.

Material: C45

Cutting Data:

Vc = 140 m/min

Vf = 0,5 mm

Application Example 7: Gear Milling

GROOVE MILLING (linear)

Special milling cutter type M275 with indexable inserts type S275 and KM arbor.

Material: 20MnCr5

Cutting Data:

Vc = 220 m/min

fz = 0,03 mm

Modular Threading Die

Threading die for pipe threads, constructed as a changing system

Consisting of:

- Basic holder

- Individual inserts

The weight of the 5 carbide cutting inserts is only 23g.

When the tool life comes to an end, the user only has to replace the cutting edges or cutting inserts, rather than the entire threading die as before. This results in considerable cost savings. Customer benefits: increasing productivity whilst conserving resources and reducing cost.