Ultra Hard Cutting Materials

Monocrystalline diamond (MCD), Polycrystalline diamond (PCD), CVD-D diamond, cubic boron nitride (PCBN)

Definition of Ultra Hard Cutting Materials

All cutting materials that are classified above carbides, cermets and cutting ceramics on the hardness scale.

Application of Ultra Hard Cutting Materials

Choosing the right application is crucial when it comes to maximising the huge potential of PCBN and diamond cutting materials in manufacturing.

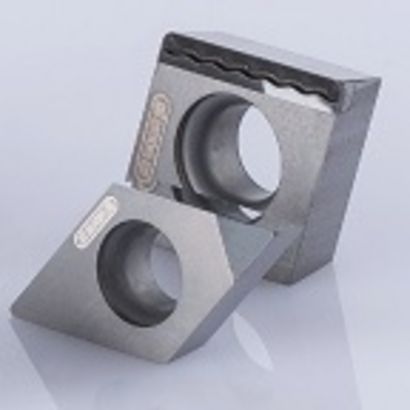

Learn moreTipped ISO Inserts

Diamond tipped with HORN chip breakers .HN and .HS

Other features include:

- Geometry .H6 positive rake angle

- Geometry .H0 neutral rake angle (ISO standardization ... W)

- Wiper (wide finishing) geometry

- Maximum chip cross sections through make-stocked and full-face designs

- Improved machining of aluminum wrought alloys

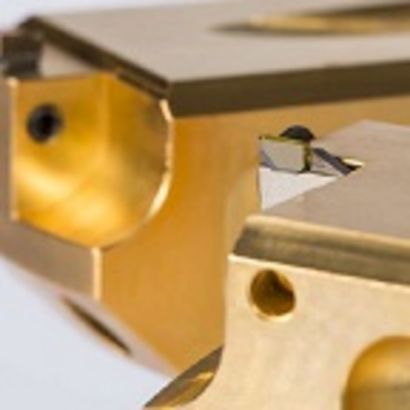

Face Milling Tool System DTM

In conjunction with the DTS inserts the DTM milling system meets high demands of surface quality together with high feed rates.

- Perfect axial run out with μ-precise adjustment for optimum surfaces

- Triple tooth feed by asymmetric tooth pitch

- Cutting speeds of up to 4500 m/min with internal coolant supply

CVD-D Milling Tool System DS

Spherical and torus mills with center cutting and multi-edged end mills for delamination-free trimming of fibre composites

- As an extension to the classical PKD

- To increase productivity

Used also for machining highly abrasive materials such as ceramics, various advantages include:

- Significant increase in service life

- Better geometric accuracy

- No chipping of the workpiece edges

High Polish Turning with MCD

MCD tipped or coated tools for internal or external machining and for use on ISO systems.

When machining highly polished surfaces with corresponding lathes no scratches are detectable, even at extreme magnification.

Reduces operations such as re-polishing due to roughness Rz less than 0.1 microns.

High Polish Milling with MCD

Tools for the following requirements:

- Non-ferrous metals with a mirror glass finish.

- Transparent plastics with undisturbed and undistorted areas

- When there is a need for no further polishing operations

- Ball milling radius from 0.05

- Plan area of up to 200 mm width

Special solutions customizable for individual requirements.

System Supermini® PCBN Tipped

Tools for internal turning and spindles

- Complete machining without subsequent grinding process

- For use on conventional lathes

- Combined with the complete Supermini® toolholder range

Internal turning of hardened steel:

- From a diameter of 3 mm

- Roughness around Rz1

- Dimensional accuracy with fitting tolerance values

System Mini PCBN Tipped

Tools for internal turning and spindles

- Complete machining without subsequent grinding process

- For use on conventional lathes

- Combined with a complete mini-holder program

Internal turning of hardened steel:

- From 6.8 mm diameter

- Roughness around Rz1

- Dimensional accuracy with fitting tolerance values

System 229 PCBN Tipped

Tools for external / internal machining, grooving and longitudinal turning of hardened steel.

- Internal machining diameters from 38 mm

- Lancing widths of 3 to 6 mm

- Two different PCBN substrates

Combinable with the complete toolholder range in the field of 229 inserts.